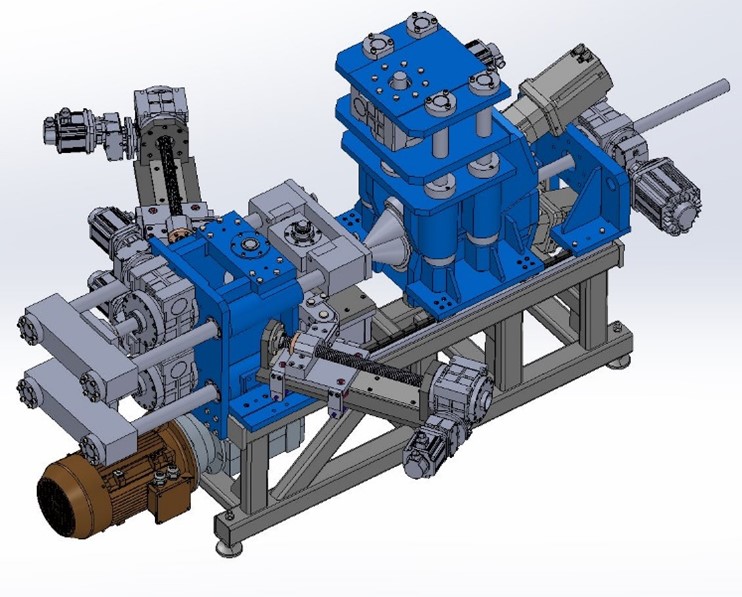

Volumetric metal forming

Metal forming includes shaping methods such as forging, pressing and extrusion. It has found wide application in the production of components for many industries. These include, for example, the automotive, aerospace, shipbuilding, railway, oil and gas industries. We provide comprehensive services for these methods with numerous industrial implementations, research and development work and patents.