Materials technology and research

We are engaged in the development of innovative material technologies and applications of materials in the field of production and operation of agricultural machinery. The team, using specialized laboratory equipment, carries out scientific and research work in the field of materials engineering within the framework of research, development and European projects, as well as service activities for enterprises. Activities are supported by close contacts with enterprises.

NON-ACCREDITED TESTING

Materials technology and research – the offer:

- STRATASYS DIMENSION 1200ES 3D PRINTER

We provide services in rapid prototyping of models by 3D printing based on FDM incremental technology. The model is built by layered deposition of thermoplastic material. The printer allows the model to be made directly from the electronic version of 3D documentation (STL file). Creating a physical model of an object using incremental methods means that there are no limitations on shape and complexity. Thanks to computer control, the fabricated models are fully reproducible and have high manufacturing accuracy. Example applications: packaging prototypes, industrial designs, parts, etc. Basic parameters of the device: chamber dimensions 254x254x305 [mm], layer thickness 0.254 mm, used material: ABS Plus.

Rapid Prototyping – example of a piece printed on Stratasys Dimension 1200es 3D printer

- FORMLABS FUSE 1+30W PRINTER

We provide services in rapid prototyping of models by 3D printing method based on SLS incremental technology. SLS (Selective Laser Sintering) technology is one of the basic methods of rapid prototyping, whose characteristic feature is selective bonding of successive layers of powder. The laser used in the method sinters the particles of the powdered thermoplastic polymer, then fusing it into successive layers. The printer allows to make a model directly from the electronic version of 3D documentation (STL file, obj). Basic parameters of the device: dimensions of the working chamber 165x165x300 [mm], layer thickness 110µm, materials used: Nylon 11, Nylon 12, Nylon 12GF. Example application: in prototyping, as well as in small batch production of functional plastic parts with good mechanical properties.

- FORMLABS FORM 3L PRINTER

We provide services in rapid prototyping of models by 3D printing based on incremental SLA (Stereolithography) technology. The manufacturer of the printer has developed a better version of printing with photopolymer resins called LFS (Low Force Stereolithography™), which provides even higher precision of manufacturing with increased printing speed. Basic parameters of the device: working chamber dimensions 335x200x300 [mm], layer thickness 25-300µm, materials used: from flexible materials to more durable and abrasion-resistant materials.

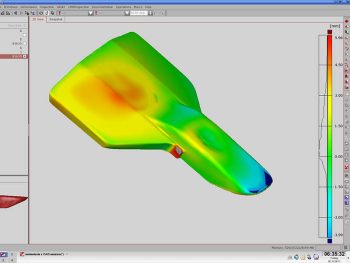

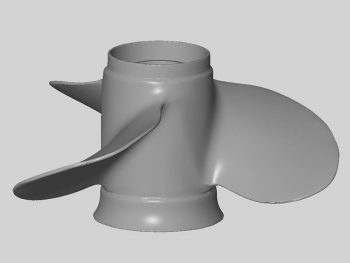

- 3D GOMATOS II scanner

We provide comprehensive services in the use of 3D scanning technology using 3D scanner GOMATOS II. The device allows you to perform scans of parts and on their basis create a 3D model, measurements of surface shape, hole spacing, etc., verification of the accuracy of the workpiece, etc. It is possible to determine differences in actual dimensions and dimensions resulting from construction documentation, e.g. testing of parallelism, alignment, perpendicularity, flatness, etc. Basic parameters of the device: Measuring fields from 175 x 175 mm to 500 x 500mm, accuracy of 0.01 mm, free orientation of the object in space.

3D scanning – examples

In addition, we provide 3D scanning services using the ATOS II device and the HandySCAN BLACK 3D handheld scanner.

We provide comprehensive services in precision measurement of structures after manufacture and determination of differences in actual dimensions and dimensions derived from construction documentation and after service life, under the influence of actual loads on the structure, using GOM TRITOP coordinate measuring machine. We have experience with objects of up to 4 m in length.

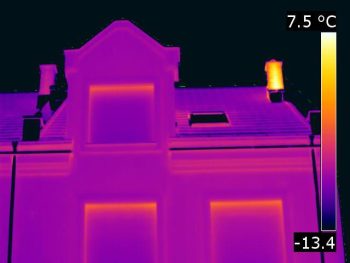

We offer the service of examining with the FLIR SC620 thermal imaging camera of various processes in which heat is emitted. The device allows recording of thermal radiation emitted by physical bodies and allows imaging of temperature distribution on the surface of the objects under study. Possible applications: research of heat flow, temperature distribution of equipment, determination of places of increased temperature, examination of temperature of processes, heating, overheating, cooling, thermal bridges, thermal insulation, climate chambers, refrigeration, etc. Basic parameters of the camera: temperature resolution 0.065C, detector resolution 640×480 dpi. temperature range -40 + 500C, spectral range 7.5 -13 um.

Our section is equipped with a SOLARIS CCD PLUS spark spectrometer for precise analysis of chemical composition. The test is destructive, and the analysis requires a sample that is capable of tightly covering a hole in the measuring table with a diameter of 8 mm.

We carry out tribological property tests on T-01 and Amsler machines and an abrasive bowl designed and manufactured by us, used to assess the wear of materials and components.

See also the offer of material surface testing

Our expert:

Joanna Sulej-Chojnacka

Phone: +48 887 800 052

Łukasiewicz Research Network – Poznań Institute of Technology, Centre for Sustainable Economy, Research Group for Materials Engineering, 14 Jana Pawła II Street, 14, 61 – 139 Poznań, Poland