Testing of metal products

Our laboratory carries out micro-area chemical composition tests using the EDS method, corrosion resistance tests, surface roughness measurements, fatigue tests and strength tests on small-sized samples.

NON-ACCREDITED TESTING

Testing of chemical composition by spetrometric method

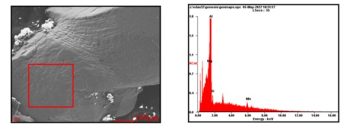

Chemical composition studies by EDS

We analyze various materials with an EDS X-ray microanalyzer, allowing, among other things, to analyze the elemental content on the cross-section of layers or identify impurities, for example, captured in the production process of food products.

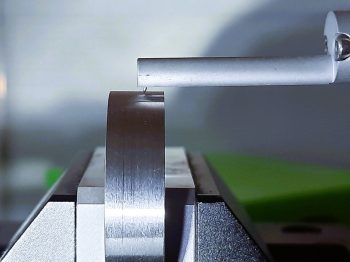

Surface roughness measurements

- using a contact profilometer with the determination of parameters for real profiles (such as Ra, Rt, Rmax, Rz, among others), ripple profile or primary profile.

Tests of corrosion resistance in a salt chamber

We perform tests according to PN-EN ISO 9227:2017-06 – Corrosion tests in artificial atmospheres. Tests in atomized brine to determine the corrosion resistance of supplied workpieces (evaluation of corrosion products formed and determination of mass change). The test chamber has the following dimensions: length 910 mm x width 710 mm x height 660 mm, which allows testing of large workpieces as well as smaller samples.

Strength testing of small-size specimens (about 7x15 mm)

Fatigue tests

Impact tests at elevated temperatures up to 600°C

During the test, the energy absorbed by the metal impact test is determined.

We test specimens standardized according to PN-EN ISO 148-1:2017-02 with V-notch or U-notch.

Determination of mechanical properties

We have portable force sensors with measuring apparatuses that allow measurements on technical objects at the customer’s site, such as presses, hydraulic systems, or structures in a wide spectrum – the smallest sensor has a range of 200 N and the largest 5,000 kN.

Resistive strain gauging supplements the measurements with the deformation that occurs in the component.

Thanks to the experience we have gained, we perform for our clients an additional service – material expertise in the field of metallurgical defects of materials, i.e. non-metallic inclusions, discontinuities of material, fatigue cracks after forging, testing of metal sheets for delamination (lamellar cracks), anisotropy of metal sheets, determination of the class of bolts and nuts, and we determine the operating defects mainly aimed at determining the cause of the crack.

Among other things, we test: fasteners, forgings, spindles, hooks, railroad and streetcar rails, traction elements, vehicle wheels, causes of corrosion, causes of cracks in welds and structures, determine the temperature of transition of the material into a brittle state, etc.

We also offer determination of compliance with the manufacturer’s declaration according to the subject standards.

See also our offer of accredited testing of metal products

Our expert

Mateusz Kukliński

Łukasiewicz Research Network – Poznań Institute of Technology, Centre for Laboratory Testing, Laboratory for Material Testing, 14 Jana Pawła II Street, 61-139 Poznań, Poland