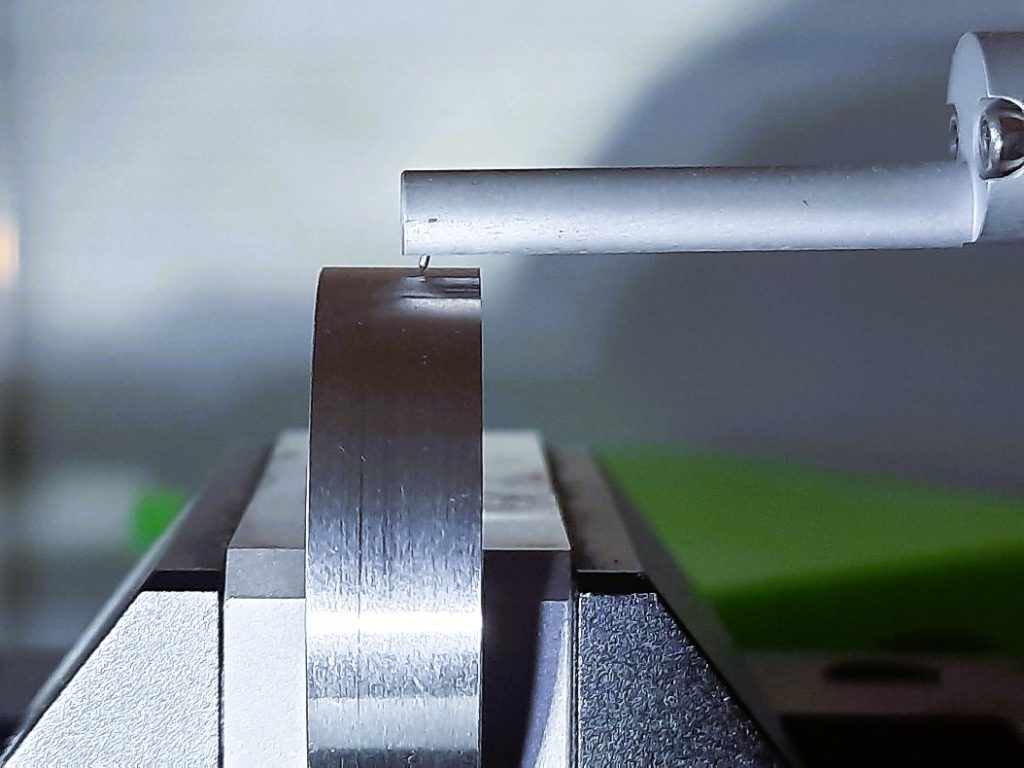

Testing of metal products

We carry out testing of chemical composition, structure and mechanical properties of mainly metal products. This ranges from simple measurements, through complex studies to multi-faceted research expertise.

We are happy to support industrial plants in solving technological problems, determining the causes of material defects, corrosion and component damage. We operate in a broad spectrum of topics and are not afraid of challenges.

Our laboratory meets the requirements of PN-EN ISO/IEC 17025:2018-02 and has been accredited continuously since 1997.