Sheet metal forming

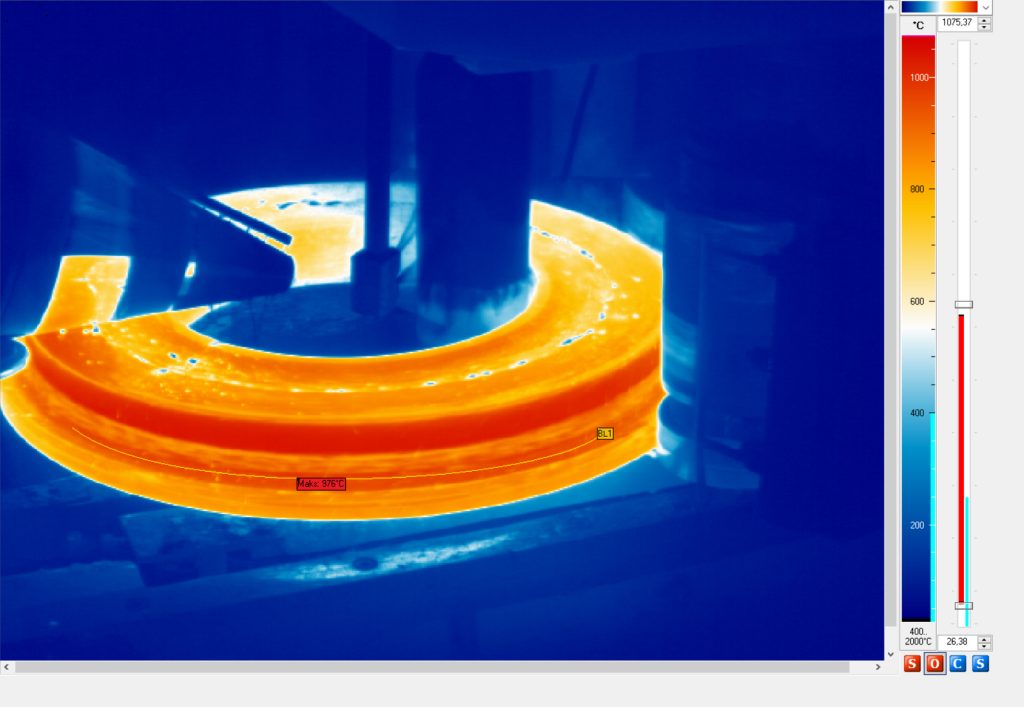

For over 70 years, we have been a leader in sheet metal spinning, carrying out prototype and small-batch orders for industry. We offer comprehensive sheet metal processing – from the development of technological processes to the production of parts, including non-standard ones. We design tools, construct machines, and implement them at the customer’s site. We work with industries such as aerospace, lighting, ventilation manufacturers, agriculture, and furniture. As part of our R&D projects, we create solutions for Industry 4.0.